Industry News

Best Jewelry Polisher Consumables for Gold and Silver

Introduction: Elevating Gold and Silver’s Brilliance

For jewelry professionals and enthusiasts, bringing out the full luster of gold and silver jewelry is both an art and a science. The right jewelry polisher tools and consumables are essential to achieve a professional shine that enhances a piece’s beauty and value. This guide explores the best jewelry polisher consumables, from equipment to polishing compounds, tailored for gold and silver. With insights into techniques and sourcing strategies, you’ll learn how to deliver a flawless finish every time.Why Professional-Grade Jewelry Polisher Consumables Matter

Basic polishing cloths offer a quick fix, but professional-grade jewelry polisher consumables are designed for deeper cleaning, effective scratch removal, and a lasting, mirror-like shine. High-quality materials protect valuable gold and silver pieces, minimizing damage while maximizing their sparkle. Investing in the right jewelry polisher tools ensures your work stands out in a competitive market.Jewelry Polisher Equipment and Consumables

Bench Polishers vs. Flexible Shaft Machines

These tools form the backbone of any jewelry workshop:- Bench Polishers: Heavy-duty machines with spindles for mounting polishing wheels. Ideal for high-power tasks requiring stability.

- Flexible Shaft Machines: Offer precision for intricate designs. Attach a handpiece to the motor for detailed work on hard-to-reach areas.

Polishing Wheels and Heads

The right wheel or head depends on the metal, polishing stage, and desired finish:

- Cotton Wheels: Soft and perfect for final, high-luster polishing on gold and silver. Options like muslin or domette vary in firmness for different tasks.

- Felt Wheels: Available in multiple densities, felt wheels apply polishing compounds evenly, ideal for smoothing intricate designs.

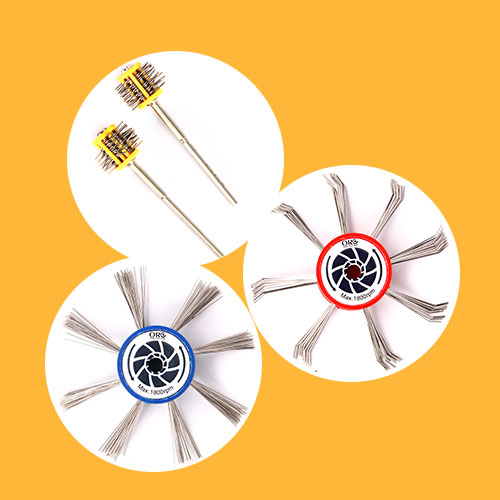

- Bristle Brushes: Great for cleaning and pre-polishing, these brushes (nylon or brass) remove dirt and light tarnish without harsh abrasion.

- Rubber Wheels and Points: Embedded with abrasive grits, these are essential for erasing scratches and prepping surfaces for final polishing.

Polishing Compounds: The Chemical Edge

Specialized compounds and liquids work synergistically with wheels to deliver abrasion and lubrication.

| Compound/Liquid | Typical Use | Notes |

| Rouge Compounds | Gold (high shine), specific gold alloys | Red rouge is a fine abrasive for final polishing. White/yellow rouge is alloy-specific. |

| Tripoli Compounds | Initial polishing of various metals (including silver) | Aggressive formula for scratch and imperfection removal. |

| Jewelers' Rouge (Iron Oxide) | Gold and some silver alloys (brilliant finish) | Ideal for achieving ultra-high luster on precious metals. |

| Silver Polishing Compounds | Silver | Specially formulated to remove tarnish (silver sulfide). Available in cutting and finishing grades. |

| Ultrasonic Cleaning Solutions | Pre-cleaning jewelry (all metals) | Used in ultrasonic cleaners to eliminate debris before polishing. Not a polishing agent but critical for preparation. |

Mastering the Jewelry Polisher Process for Gold and Silver

Polishing gold and silver requires tailored techniques due to their unique properties.

Metal Properties and Polishing Needs

- Gold: Soft and prone to scratches, gold demands gentle jewelry polisher compounds, especially for higher karatages (e.g., 18k, 22k), to avoid material loss.

- Silver: Also soft, silver tarnishes easily due to sulfur exposure. A jewelry polisher must remove tarnish without over-abrading the surface.

Advanced Polishing Techniques

- Graduated Abrasion: Start with coarser wheels or compounds to tackle deep scratches, then switch to finer grits for a smooth, refined surface.

- Precision Polishing: Use small felt bobs, rubber points, or micro-tools under magnification for detailed areas, ensuring the jewelry polisher reaches every crevice.

- Protecting Gemstones: Mask or avoid gemstones during polishing to prevent damage from abrasives or heat generated by a jewelry polisher machine.

Post-Polishing Care

- Cleaning: Rinse away residual compounds with mild soap or an ultrasonic jewelry polisher cleaner to prevent buildup.

- Drying: Thoroughly dry jewelry to avoid water spots or tarnish.

- Silver Protection: Apply anti-tarnish coatings or use specialized cloths to slow oxidation, extending the shine.

Choosing the Best Jewelry Polisher Consumables

Selecting high-quality jewelry polisher consumables and reliable suppliers is key to consistent, professional results.

Factors to Consider

- Brand Reputation: Choose trusted manufacturers known for consistent, high-quality jewelry polisher products.

- Material Quality: Opt for durable polishing wheels and compounds with uniform abrasive particles for reliable performance.

- Longevity and Effectiveness: Evaluate how long consumables last and their ability to deliver a professional shine.

- Cost-Effectiveness: Balance quality with affordability, ensuring jewelry polisher consumables offer good value over time.

Sourcing Strategies

- Direct Manufacturers vs. Distributors: Buying directly may save costs, while distributors often provide broader selections.

- Technical Support: Partner with suppliers offering expert advice on jewelry polisher consumable selection and use.

- Reliable Supply: Ensure consistent access to your preferred jewelry polisher materials to avoid workflow disruptions.